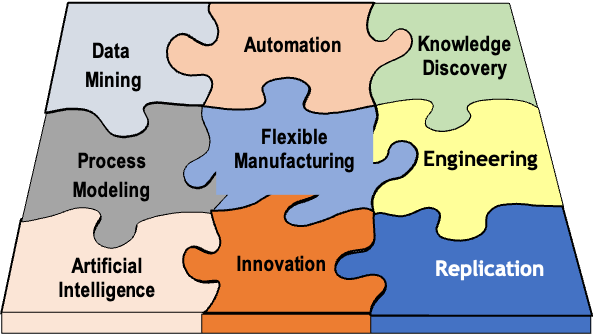

VINTEK succeeds in its work through Scientific Engineering.

Science is used to gain knowledge about processes which is then applied in Engineering to achieve higher performance.

Flexible manufacturing technology is necessary. At VINTEK, smaller size castings are produced using Co2 air-set method and bigger size castings up to 4 tons in weight are produced using resin moulding method.

Automation is essential particularly in a large foundry such as VINTEK.

Data Mining, Knowledge Discovery and Artificial Intelligence are all scientific disciplines that offer useful techniques to gain valuable insights from data. Business process is modeled to meet product specifications and achieving customer goals.

Scientific Engineering happens in a new dimension combining knowledge gained from all steps.

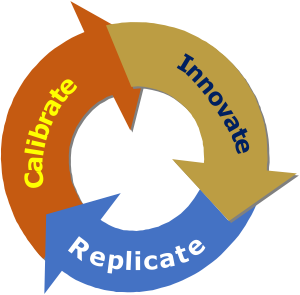

The modus operandi of VINTEK is to follow a cycle of Innovate, Replicate and Calibrate.

Innovation occurs during optimization of local sub-processes and global foundry process. Local optimization can sometimes conflict with global. Therefore, careful attention must be paid to achieve an ideal trade-off. Strong knowledge and experience in scientific engineering is very essential to be successful.

Replication ensures consistency in operations when moving from sample development to bulk production.

Calibration minimizes variance.

VINTEK educates its team and trains them in tradecraft which allows them to solve problems and return the system to a balanced state.